“`html

Smart Ways to Measure a Box Effectively in 2025

In the world of shipping, storage, and crafting, knowing exactly how to measure a box is crucial. Whether you need accurate box dimensions for shipping purposes or are working on a home project, mastering box measurement techniques will save you time and hassle. This article will explore effective methods on how to measure a box accurately while focusing on tools, tips, and formulas that can help you in 2025.

Understanding Box Measurement Techniques

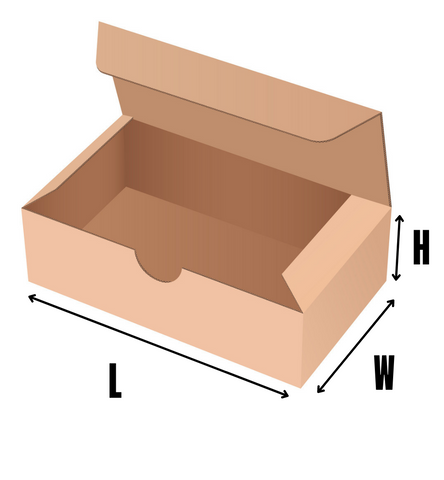

Before diving into specific methods, it’s important to have a grasp of box measurement techniques. Accurate measurements ensure your box fits its intended purpose, whether it’s for shipping, storage, or crafts. Understanding the **dimensions of a box**, which includes measuring length, width, and height, is essential. The first step in measuring a rectangular box involves laying it flat on a surface to make readings more manageable.

Measuring Length and Width

To start with measuring length, position your measuring tape or ruler at one end of the box and extend it to the opposite end. Record this measurement. Next, measure the box’s width similarly, ensuring you maintain a level alignment across the edges to prevent any discrepancies in reading. When measuring boxes for shipping, be mindful that accurate box size measurement can significantly affect shipping costs and material distribution.

Measuring Height and Depth

Moving on to measuring height, place the measuring tool vertically along the side of the box, ensuring it touches the base and extends to the top edge without slanting. This is crucial for attaining accurate box measurement. For deeper boxes, consider measuring the depth of a box as well, especially when assessing capacity and volume needs, using the same principles as height measurement. You can use this technique to measure deeper containers without the need for complex tools.

Tools for Measuring Boxes

Investing in the right tools for measuring boxes will improve your accuracy. Measuring tapes are essential; they should be flexible yet sturdy, allowing you to measure both straight-edged and irregular boxes. Consider using a box calculator tool to convert these measurements into volume or area, aiding in your understanding of box capacity and necessary materials for filling or packing. Tools often used include retractable tape measures, calipers for precise edge measurements, and marking tools for delineating measurements on the box itself.

Digital Solutions for Accurate Box Measurement

In 2025, leveraging technology can enhance your box measurement experience significantly. Various digital apps and box calculators can automate much of the measuring process, allowing for quick calculations of volume and area based on input measurements. By integrating these tools into your measurement workflow, individuals and businesses can achieve higher accuracy and efficiency.

Using Box Measurement Apps

Explore download options for box measurement apps that help in calculating box volume and optimizing space. Input the recorded measurements, and the app provides instant results. Many of these applications also offer features like estimating shipping costs based on box size, which could be immensely beneficial for businesses. Utilizing modern solutions not only streamlines the measuring process but also reduces human error.

Online Box Measurement Tools

Numerous websites offer free online tools for measuring boxes for shipping. These tools allow you to input dimensions into an online calculator that can output volume, cubic weight, and shipping estimates. Prioritizing these tools can help you navigate the complexities of shipping logistics effortlessly. Make a habit of using these digital solutions to make your workflow more productive.

Integrating Digital and Physical Tools

The blending of traditional and advanced measurement techniques ensures a comprehensive understanding of effective box measurement. While digital solutions can provide immediate calculations, manual methods still underpin the foundation of box measurement accuracy. Strive to use both a reliable measuring tape and a digital tool in tandem to achieve the most effective results.

Best Practices for Box Measurement

The precision in box measurement can dramatically reduce shipping errors and enhance storage solutions. Incorporating standard box size measurements into your techniques ensures consistency and repeatability during your projects. Knowing how to find box volume efficiently is also paramount.

Box Measurement Standards

When measuring items in a business, familiarize yourself with box measurement standards for your industry. Many industries have established systems for understanding box size implications on logistics and warehousing capacities. For example, knowing your standard box sizes can facilitate easier stock management and order fulfillment.

Avoid Common Measuring Mistakes

Familiarize yourself with typical mistakes when it comes to measuring box size to circumvent avoidable errors. One common mistake arises from improper alignment of the measuring tape. Always ensure it’s straight and not sagging when you take measurements. Additionally, make use of clear visibility to avoid incorrect readings caused by obstructed views or misinterpreted measuring units.

Measuring Irregular Shapes

Sometimes, you may find yourself needing to measure irregular box shapes. For such instances, measure the largest dimensions and compare them with the box’s interior to ensure the contents will fit comfortably. Using tools like a caliper allows for clearer readings of more complex geometries and shapes. Always double-check your findings for any unexpected discrepancies that might arise.

Key Takeaways

- Accurate box measurement involves knowing how to measure length, width, and height properly.

- Integrating technology such as box measurement apps can enhance accuracy and save time.

- Understanding box measurement standards ensures your measurements are reliable and consistent.

- Avoid common mistakes to improve your box measurement accuracy and efficiency.

- Measuring irregular boxes requires specific techniques and tools for effective results.

FAQ

1. Why is accurate box measurement important?

Accurate box measurement is vital for ensuring that items fit appropriately within packaging, which prevents damage during shipping and storage. Additionally, precise measurements help companies calculate shipping costs and optimize shipping logistics, ultimately affecting profitability.

2. What are the common mistakes in measuring boxes?

Common mistakes include misalignment of the measuring tape, not measuring all dimensions (length, width, height), and unclear or squished readings due to improper technique. Ensuring correct alignment and using appropriate measuring tools can prevent these errors.

3. How can I measure irregular shapes effectively?

To measure irregular shapes, capture the largest dimensions and check interior capacity. By using flexible measuring tools, such as measuring tapes or calipers, you can obtain better readings, ensuring that the object fits inside the box dimensions accurately.

4. What tools do I need for box measurement?

Primary tools for accurate box measurement include measuring tapes, rulers, and calipers. Additionally, digital apps for box measurement or box calculators serve to streamline the process by performing complex calculations and estimations with ease.

5. How can measuring tools impact shipping costs?

Using the proper measuring tools provides accurate dimensions that directly influence shipping costs. Shipping companies typically charge based on volume, so misunderstood measurements can lead to higher fees or unsatisfactory delivery forms. Ensuring accuracy reduces unnecessary costs while optimizing shipping processes.

“`